Modern adhesive technologies utilize both singleand two coat adhesive formulations with the preference depending upon the service needs of the bonded assembly.

Rubber to metal bonding pdf.

In reality a great deal of technology backs the apparently simple action of bonding.

By taking six steps beginning with part design and ending with testing the rubber molder and the manufacturer can ensure the bond is strong enough for the application and its operating environment.

Rubber to metal bonding preparation to begin the bonding process the metal inserts are first prepped for production using a degreasing system to rid the parts of any contaminants before the adhesive is applied.

The adhesives being used sometimes functioned like metal glue and had limited process versatility which resulted in high scrap rates due to poor bond.

Rubber not only produces a very strong bond on metal but it also can be used to combine several parts into a single assembly.

Strong rubber to metal bonding can be obtained with sr633 for a variety of rubbers as shown in figure 6 for silicone rubber eva epdm natural rubber and hypalon.

Bonding different materials together by means of an adhesive may appear to most people as a mundane occurrence.

A suitable evaluation for rubber metal bonding and also the ability of rubber phase for energy dissipation 59 62.

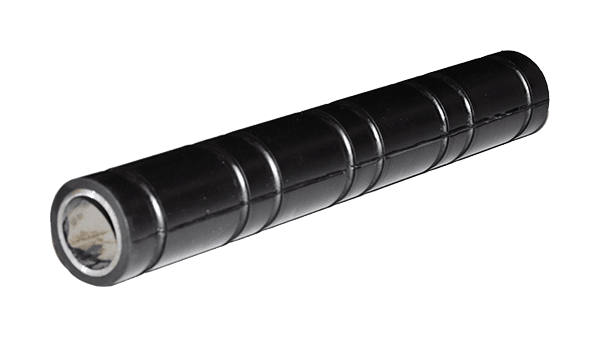

Bonding rubber to metal is a means by which rubber is mechanically bonded to a metal insert during the molding process.

Each step is dependent on the success of those that preceded it and the stages are numerous and complex.

Chemlok elastomer bonding guide introduction in 1956 lord corporation commercialized a chemlok primer and covercoat system that produced elastomer tearing bonds with virtually all commercially available elastomers.

The process was first introduced about 140 years ago when it was.

Knowledge of the fundamentals of bonding rubber to metal was lacking.

Historically several bonding methods have been employed within the rubber industry in an effort to achieve a dependable and durable rubber to metal bond.

Thus a complex and advanced technology or series of technologies has arisen to deal with adhesives and their applications in many fields.

Rubber to metal bonding is a means by which rubber is mechanically bonded to a metal component during the moulding process.

Cohesive failure is the predominant mode of failure in each rubber compound.

Rubber material without a bonding layer must be keyed using a buff with 24 grit and if stored for a long time the bonding layer material.

This quantum jump in technology provided a broad processing latitude for bonding and drastically reduced scrap levels.

In each case shear adhesion is significantly increased with the sr633 cure system over the peroxide control.

.png?width=838&name=Untitled%20design%20(6).png)